- All film welding is done in a clean factory environment – welding the film in the presence of sawdust/metal dust (or similar) will result in poor-quality weld joints, which may burst during transportation or when stored in windy conditions.

- Less damage to the packaging and the module underneath – the packaging does not wobble in the wind and during transport and does not become damaged or damage the module.

- Easy and quick to install – by following the procedures described above, modules are usually packed in minutes. For example: packing a 15 x 4.0 x 4.0 module takes two people a total of 30 minutes (10 minutes for rolling the packaging open and providing with strips + 20 minutes for heating and taping the packaging).

- There is no need to store different film rolls in the warehouse for different packaging needs – each package is custom made for a specific module!

- Does not produce waste – provided that the measurements have been accurately communicated, the packaging is prepared so that no waste (film residue) is generated during packing.

- Quick removal (< 5 minutes) – there are only a few strips and the film is cut open. The film can also be cut apart in sections by removing only the side that goes against the other module or by removing all sides, leaving only the film on the roof, which holds at the edges until the last minute. This way, modules can be temporarily protected from precipitation during construction work.

- Continuation of construction work in a module pre-packaged at the factory thanks to the film doors which can be added to the packaging, if necessary.

- Less strip installation = faster work at the plant and in construction assembly, less damage to the facade and fewer possibilities for water damage.

- Standardisation of work – all packaging is performed using the same method and work procedures.

- Aesthetic packaging/look – the marketing side faces the customer.

- Packaging with UV protection

- Safer work – less working at height, standardisation of the process.

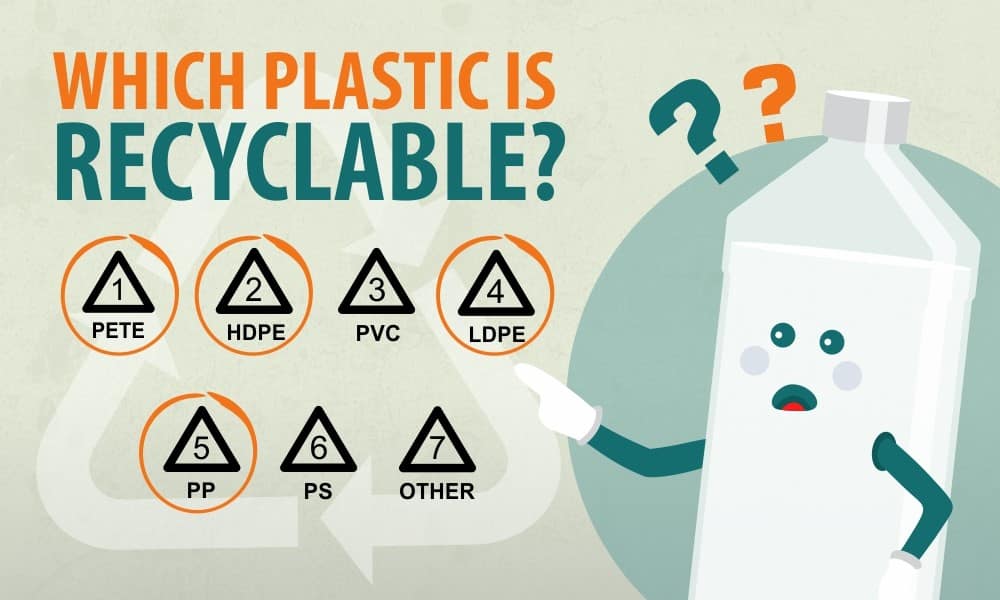

Please note! After removal of the film, the packaging should be cut into panes and rolled together (in order to reduce waste) and sent to the recycling facility for recycling.

PROTECTION

PROTECTION DURABLE

DURABLE EASY TO USE

EASY TO USE LOWER COST

LOWER COST LIGHTWEIGHT

LIGHTWEIGHT QUALITY

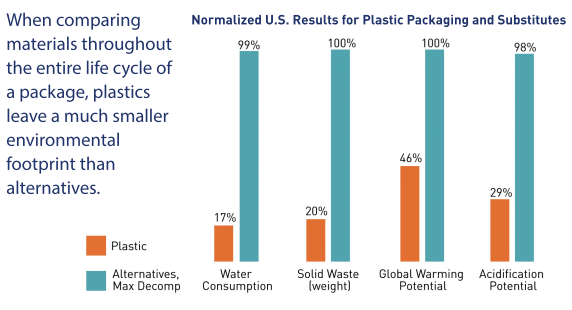

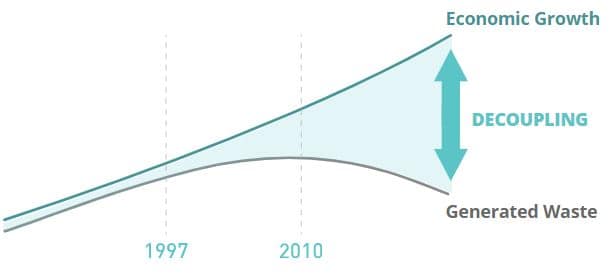

QUALITY ENVIRONMENTALLY FRIENDLY

ENVIRONMENTALLY FRIENDLY

SHIPPED WORLDWIDE

SHIPPED WORLDWIDE BEAUTIFUL OUTCOME

BEAUTIFUL OUTCOME FAST QUOTATION

FAST QUOTATION